HongRu industrial static disc sand mill is widely applied in the production of water-based and low-viscosity material. HR-PJ adopts centrifugal screen discharging with larger flow rate and final product rate. In industrial production, it could realiz.

Now HR-PJ series horizontal sand mills are widely applied in industries with high requirements for fineness and dispersion property such as disperse dye, vat dye, organic pigment, water slurry, pesticide sc etc.

| Model | Grinding Chamber (L) | Power (KW) | Speed (RPM) | Grinding Media Size(MM) | Weight (KG) |

| HR-30PJ | 30 | 20/30 | 1440 | 0.2-2.0 | 900 |

| HR-60PJ | 60 | 37/45 | 1440 | 0.2-2.0 | 1500 |

| HR-100PJ | 100 | 45/55/75 | 1480 | 0.2-2.0 | 3000 |

| HR-300PJ | 300 | 110 | 960 | 0.2-2.0 | 4000 |

| HR-500PJ | 500 | 160 | 960 | 0.2-2.0 | 6500 |

| HR-1000PJ | 1000 | 400 | 960 | 0.2-2.0 | 9800 |

|

|

|

|

|

Assembly type double end mechanical seal |

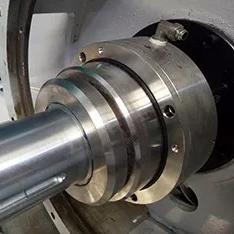

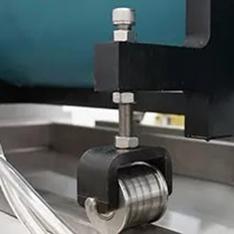

Inner chamber | Bearing seat and disc | Pulling wheel |

Assembly type double end mechanical seal with stable working property, to save the energy for frequent changing and cost for maintenance, able to realize long-time working with no sudden-stop worries.

Considerate design for easy operation. All connection parts are designed to be fast connection, saving the energy of maintenance, focusing all time on production.

Multiple cooling method in outer chamber cooling coil, high heat transmission material pulley, mechanical seal cooling, bearing cooling to better control the material temperature. With special cooling condensor, to add ensurance for temperature control.

Grinding rotor with special design to allow high efficient grinding.