Pesticide SC Production

Agricultural industry is one of the most important application industry of HongRu.We have helped more than 300 customers in China and other countries to successfully optimized production process for pesticide SC, OD, EC, EW and SL etc. The following article will focus on the production process and key technical points is pesticide sc (herbicde, fungicide and insecticide).

Production Process

What is main production process and its main technical points?

No matter which types of pesticde sc, they shares basic production process: powder charging–pre high shearing–sand mill grinding–final formulating–filling. In many customer site, they have omitted certain production process to result in low production efficiency. A better production process together with high-efficiency production equipment will greatly help customer to enchance the efficiency or reach to even finer particle size and this will in another way help to save the cost. Let’s take one customer site as example and analyze its production process and design property.

The technical points you may want to know about the line

-

How to control material temperature during the production process?

-

How to ensure that the xanthan gum could be evenly dissolved and fully utilized?

-

How to ensure a steady working of the production ?

-

How to ensure service life of bead mill equipment?

-

How to ensure an easy maintenance of production equipment?

-

How to ensure the product quality?

-

How to clean and the time taken?

-

What is the expected life time of grinding media?

-

How about the beads charging quantity and its calculation?

-

How often to clean the filter and how to clean them?

-

How about noise grade?

-

How about water, electricity and air consumption?

-

Will non automatic production line use the same production process?

-

How to ensure the particle size reach to the target?

-

If we have a production line already, can you help to optimize it by adding certain process or equipment?

The above will be the main concerns from many customer when they are doing pesticide sc or od. For all of these concerns HongRu will help to answer and eliminate your concerns. You can try to call us or send us emails to consult or tell us your requirements for production at sales@sh-hongru.com

Information Needed for Designning of a Complete Production Line

-

How many Liter to do per batch or per day?

-

The finish size requirement: for example 2-3μm or 5μm?

-

Which kind of pesticide sc you want to do: fungicide, insecticide or herbicide?

-

What is the original TC powder size?

-

What about the solid content of your formula?

-

Which product will you do? Atrazine, imidcloprid or others?

-

Will you charge the raw material manually or automatically?

-

Raw material package is 25KG or bulk bag?

-

Will you prefer manually operation, semi-auto or full auto production?

Hongru Solution

Root will provide a complete solution from production line design till installation and trainning to After sale service

-

Laboratory Research

-

Before selecting the suitbale bead mill, HongRu will offer free lab experiment for customer to do grinding test of the material.

-

Technical Design

-

2-D production line CAD flow chart and arrangement drawing (for all production line)

-

3-D production line SOLIDWORD arrangement drawing (for all production line)

-

Automatic PID drawing (for full auto production line)

-

High Quality Production

-

Bead Mill Production

-

High shearing, mixing, vessels and platform production

-

Zirconia grinding media production

-

Packing and Delivery

-

Complete production line test running before dispatching, customer can come for inspection or we will take video to show the test-run

-

Single machine packed in plywood case. Full line packed in full container

-

International Transportation Service

-

Installation and Commissioning

-

HongRu will arrange installation based on customer requirement

-

After-sale Service

-

24hrs on-line service to answer any question from customer

-

Cost price spare parts to supply to the customer always

-

Life-long maintenance whenever customer needs

Application of Equipment

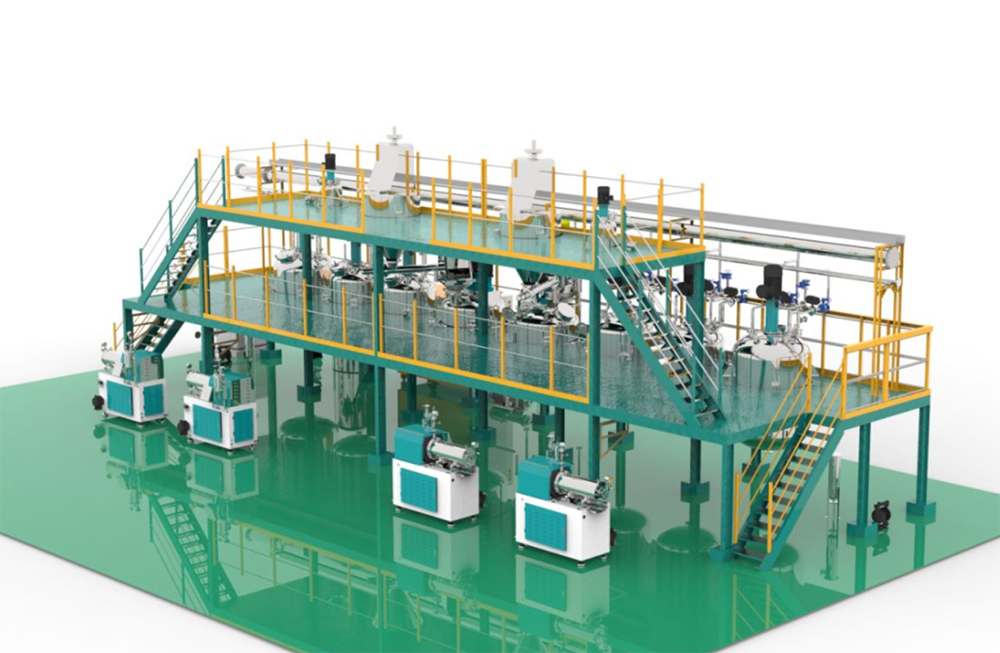

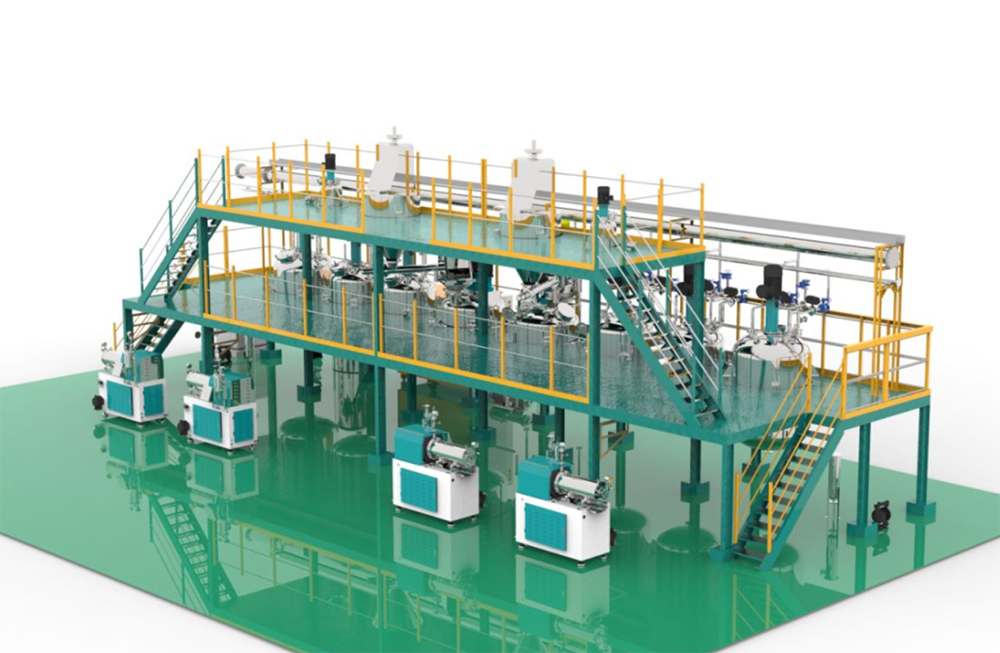

The main equipment in the line

The main equipment used inside the line are powder loading station, high shear vessels, high shear pump, horizontal bead mills, mixing vessels. All of these equipment will be adjusted based on customer detailed product and formula.

-

For a better crushing and shearing of the original Tc powder, it is suggested to use the high shear as the first high speed shearing equipment of the line and to add a high shear pump before material goes to the bead mill.

-

For the bead mill, a PD+PJ series grinding, PJ+PJ or PJ+WJ series grinding is wise choise for one pass grinding of the product

Case Study

Application projects and case studies